Artificial Muscle Brings Us One Step Closer to Lifelike Robots

Columbia University Engineering researchers, led by professor of mechanical engineering Hod Lipson, have developed a 3D-printable synthetic soft muscle. It is described as a one-of-a-kind artificial active tissue with intrinsic expansion ability that does not require an external compressor or high voltage equipment as previous muscles required. When 3D printed to imitate a muscle, it can withstand great strain and lift 1,000 times its own weight. If scientists are able to configure these muscles to be controlled through AI, it could lead to a future of extra-strong, humanoid robots.

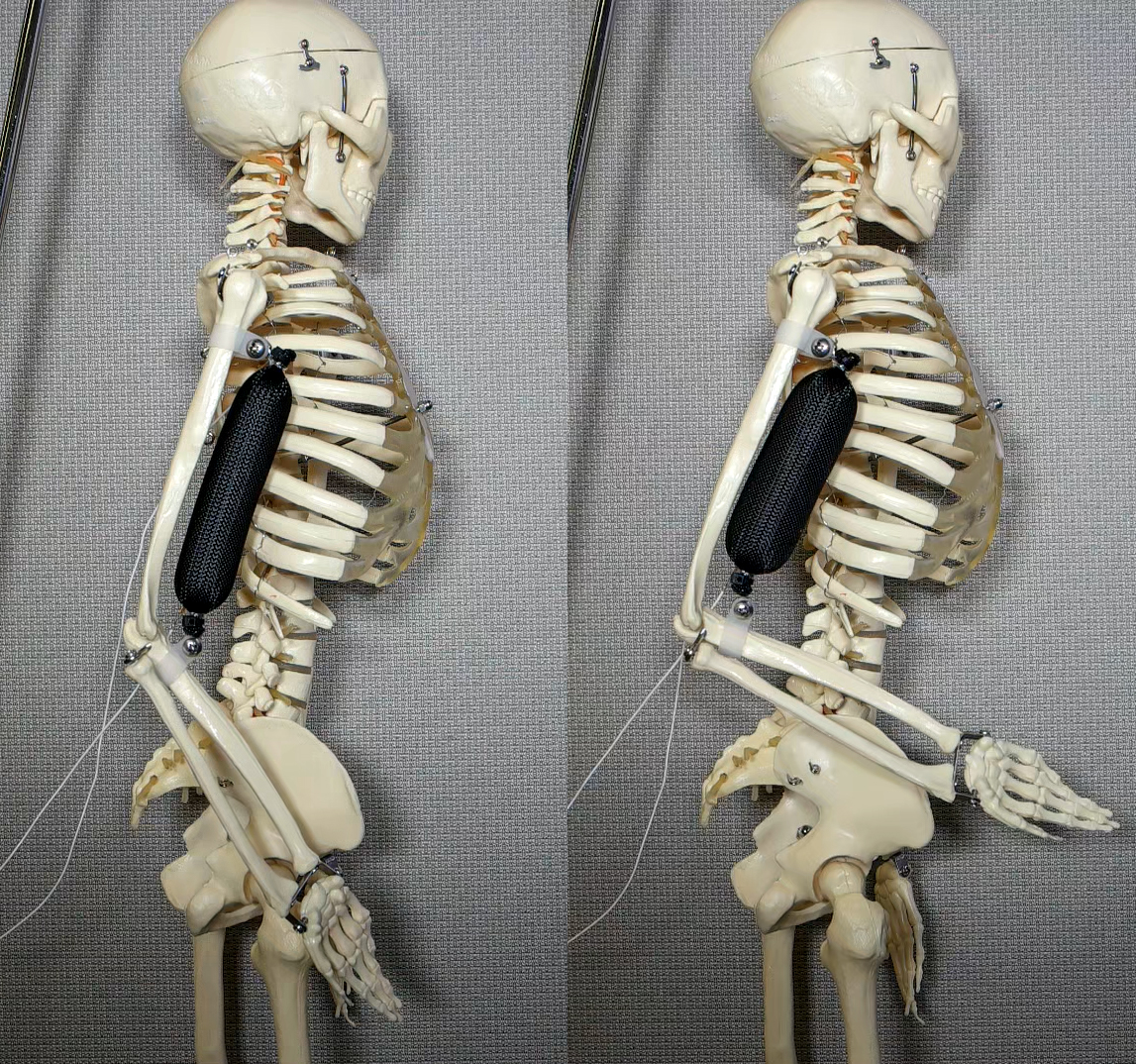

The system developed by the Columbia team is made of silicone rubber matrix pocked with micro-bubbles of ethanol. This givies the material a low density couple with high elasticity. It can be 3D printed into whatever shape is needed, then electrically actuated thanks to a thin wire embedded inside. Surprisingly, all of this can be made relatively cheap and easy.

Synthetic muscle tech is presently reliant on tethered external compressors or high voltage equipment. But, robots fitted with this new tissue could theoretically be freed up to move around like humans, enabling them to better grip and pick up objects. Which is a big deal, because the plan is to eventually get these bots to help with non invasive surgeries and to care for the elderly, among other tasks.

“We’ve been making great strides toward making robots minds, but robot bodies are still primitive,” said Hod Lipson. “This is a big piece of the puzzle and, like biology, the new actuator can be shaped and reshaped a thousand ways. We’ve overcome one of the final barriers to making lifelike robots.”